About us

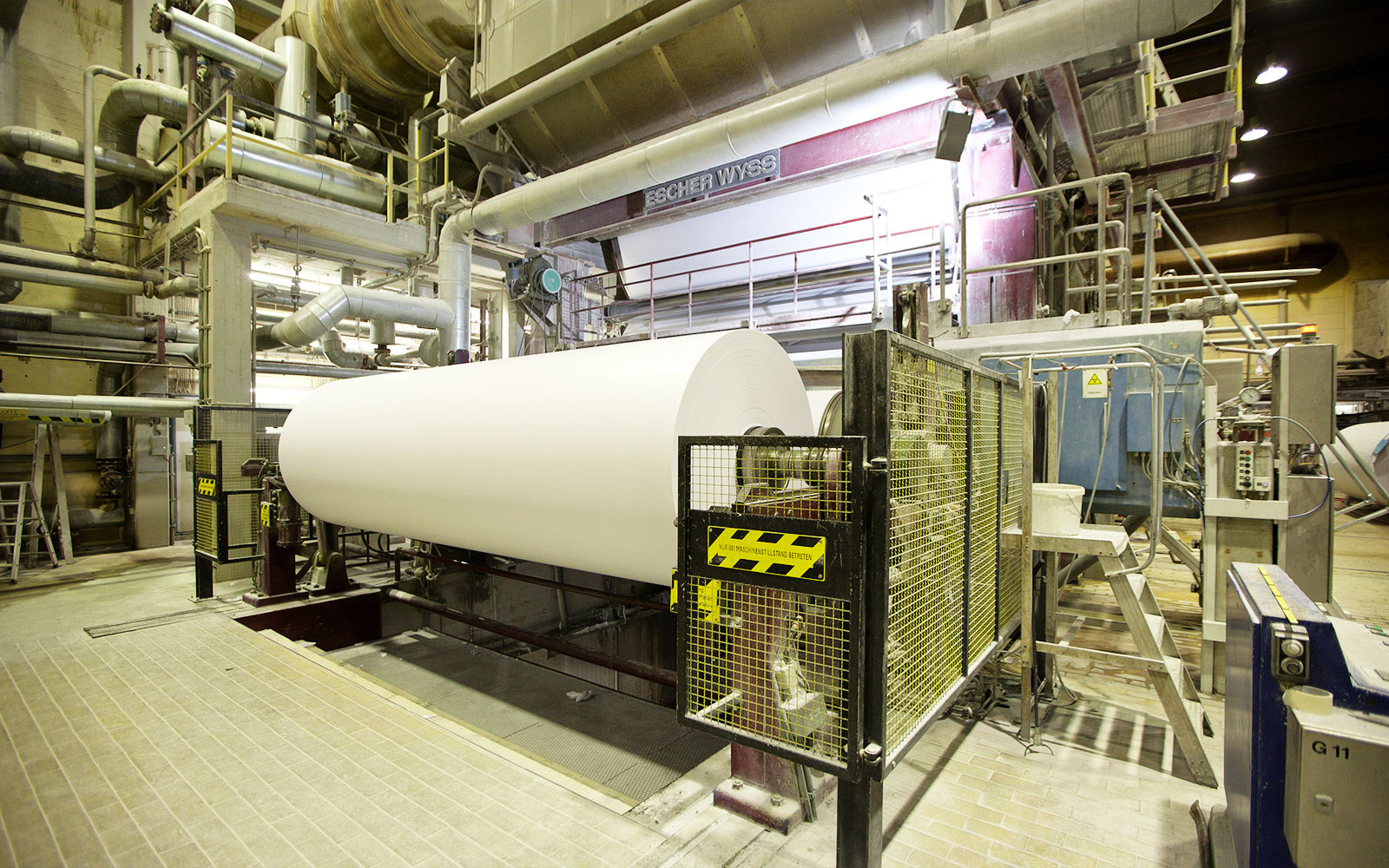

As a family business founded in 1875, we have operated a paper factory at Kirchhundem-Hofolpe since the end of the 19th century. All the shares in the business are held by members of the Grünewald family. In the fourth generation the enterprise is still headed by a member of the family.

The heart of our company is formed by the more than 100 employees of Grünewald Paper, nearly all of them being locals. All employees have a strong affection for paper. They identify with company and its products to a high degree. This is also reflected by the fact that on average each employee has worked for the company for more than 20 years. Apart from the owner family many other local families have belonged to Grünewald for generation.

Thus the majority of our employees trained in our enterprise and more than half of them possess a qualification as paper technologist, master industrial papermaker or paper engineer.